In recent years, Synergy Engineering B.V. has been at the forefront of several high-profile engineering projects, demonstrating our capability to handle complex challenges in the offshore sector. From innovative design solutions in Taiwan to logistical prowess in India and Trinidad, our projects have set new standards in engineering excellence.

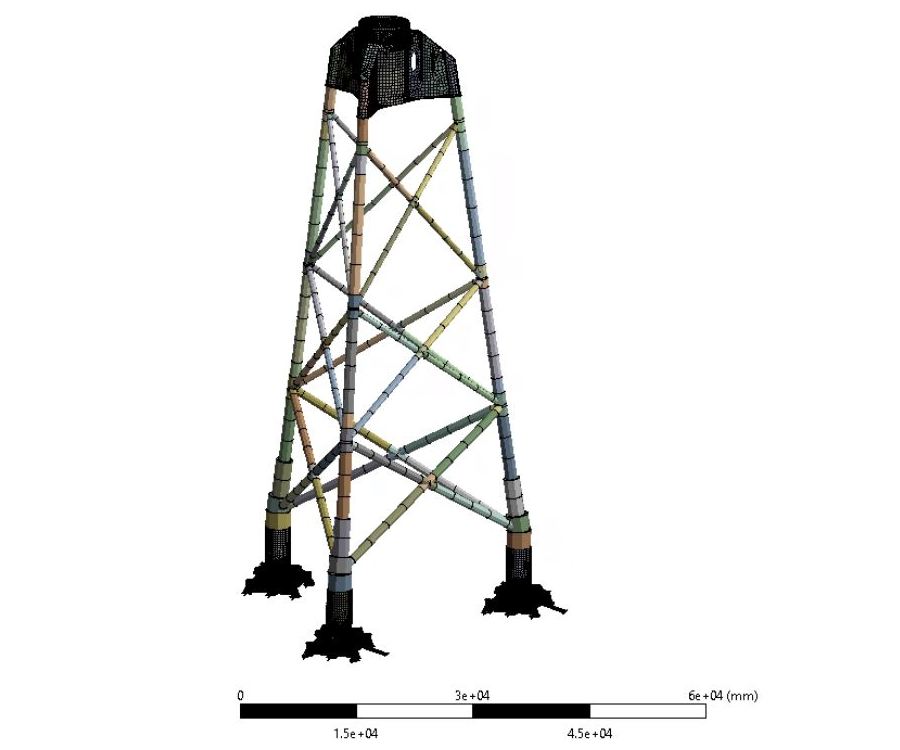

Greater Changua Wind Farm, Taiwan: Partnering with XPRTHUB, we undertook the design of Grillages and Seafastening (G&SF) for the Greater Changua wind farm. The primary challenge was creating a non-welded seafastening solution for jacket foundations. Our innovative approach involved designing hydraulically pressed clamps and conducting detailed nonlinear Finite Element Analysis (FEA), including assessments for low cycle fatigue. This project was a testament to our expertise in developing unique, reliable solutions for the renewable energy sector.

Ruby FPSO Mooring System, India: Our involvement in the Ruby FPSO Mooring System project spanned two critical campaigns. Initially, we were responsible for the Transport and Installation (T&I) of suction anchors, which included designing rigging arrangements and writing procedural guidelines. Our team’s presence during the Construction Support Vessel (CSV) mobilization in Singapore and Batam was pivotal for placing cradles and loading mooring chains and anchors. The subsequent phase of mooring line installations saw us again providing both office-based procedural support and on-site offshore assistance. Navigating the logistical challenges posed by COVID-19 travel restrictions underscored our adaptability and commitment to project success. In the depth of “COVID times”, we had words of Henry Ford in our mind:

“When everything seems to be going against you, remember that the airplane takes off against the wind, not with it..” – Henry Ford

Jackup Leg Salvage Offshore Trinidad: In a race against time, we designed a 1500-ton lift frame and G&SF for a jackup leg salvage operation offshore Trinidad. The urgency of the project, coupled with local material availability constraints, demanded rapid yet precise engineering and fabrication. Our ability to deliver under such tight timeframes and conditions highlighted our proficiency in managing high-pressure scenarios while maintaining quality and safety standards.

The diverse challenges and successes of the Greater Changua wind farm, Ruby FPSO Mooring System, and the Trinidad jackup leg salvage project reflect Synergy Engineering B.V.’s versatility and expertise in the offshore engineering sector. Each project underscores our commitment to delivering innovative solutions, maintaining stringent safety standards, and overcoming logistical hurdles, regardless of the project’s scale or location.